Home / KL-CTDS

KL-CTDS

Smart Industrial Torque Display

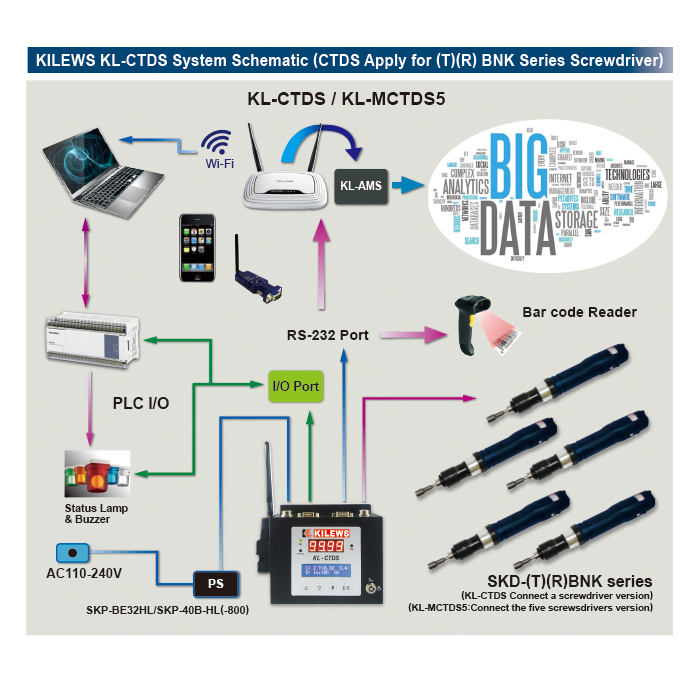

In the era of Industry 4.0, assembly date collection and integration is becoming a must. In order to meet market demands, Kilews’s latest invention KL-CTDS is able to display tightening torque, output tightening torque, output tightening status, storage tightening torque and together with error proof functions. KL-CTDS is also able to prevent errors from tightening torque, tightening number of threads, and tightening time. With various I/O, KL-CTDS can be connected to your PLC and integrated with your automation equipment and output assembly status instantly to your server or private could by Ethernet or WIFI for traceability.

KL-CTDS

Product Specification

| Model | KL-CTDS |

| Input voltage | DC32V/40V |

| I/O Output voltage | DC24V 50mA/ 12V 100mA |

| Count | 1-99 |

| Count method | Count-up/ count-down |

| Continued induction switch (sensor) | ON/OFF |

| Sensor switch mode | ON (2 sensors)/ OFF (1 sensor) |

| Slow start setting time | 0~9.9 seconds |

| Slow start speed setting | L0:100%, 10%~90% L1~L9 Rated speed |

| Dedection stop time | 0.00~9.99 seconds |

| Dedection torque value | 0.0~550.0 kgf.cm |

| Dedection screw thread number | 0.0~999.9 |

| External connection input | Forwarder/ reverse/ disable/ confirm |

| External connection output | OK/ NG/ OK ALL/ STOP |

| Serial interface | RS-232x2 |

| Assembly management | KL-DAS/ KL-AMS |

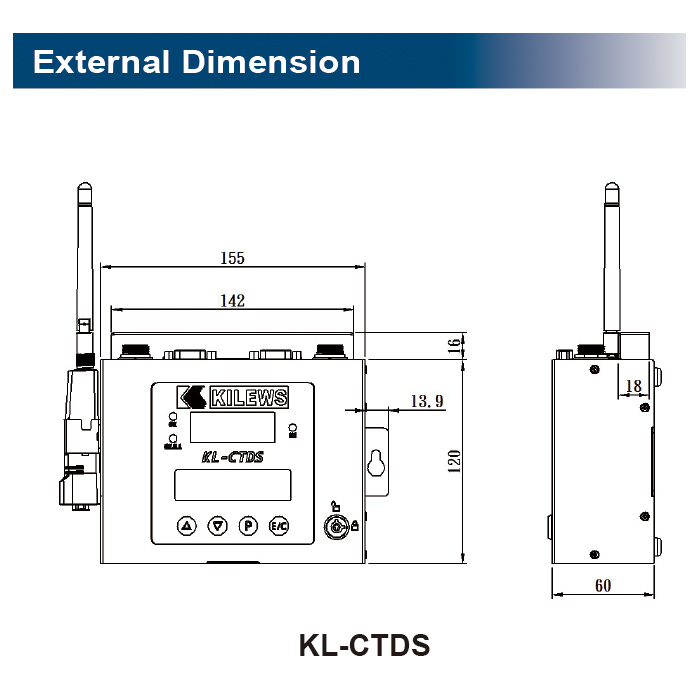

| External dimensions | 155x120x60 (mm) |

| Weight (g) | 622.5g |

| Accessories | Power cablex1/ Keyx2 |

| Applicable models | SKD-BNK200/500/800/900 series |

| SKD-RBNK series | |

| SKD-TBNK series |

Product Features

● 16x2 LCM display settings

● Password and key control to avoid operator adjusting settings

● Counting preference set up (count up and count down)

● Slow start time 0.0-9.9sec

● Slow start speed (10%~90%, L1~L9)

● Workpiece in place sensor (on/off)

● Set up fastening thread range

● I/O signal (optcoupler)

● RS-232 interface for data output, storage and use with barcode scanner

● Set up fastening time range

● Set up fastening torque range

● Error code

● Auto learning

● Change torque unit

● Offset setting

● External start

● External reverse

● External disable tool

● External confirm